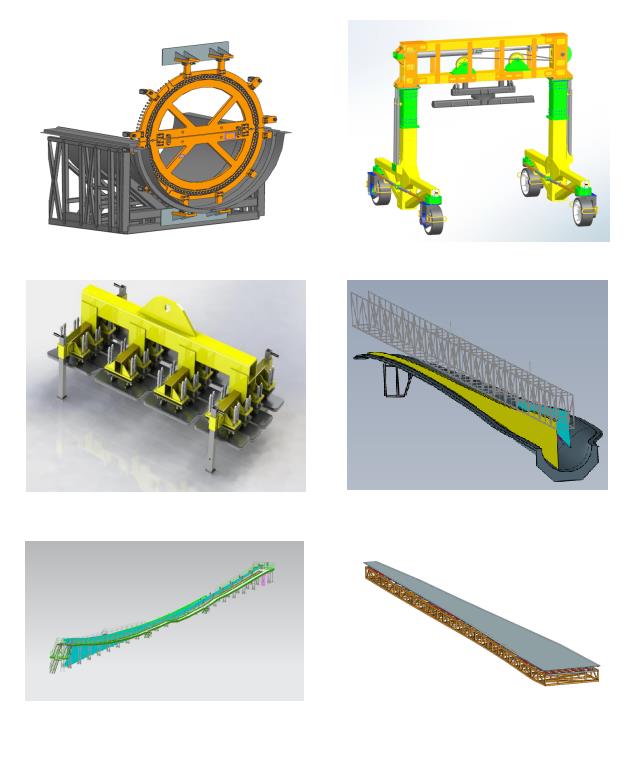

Product

-

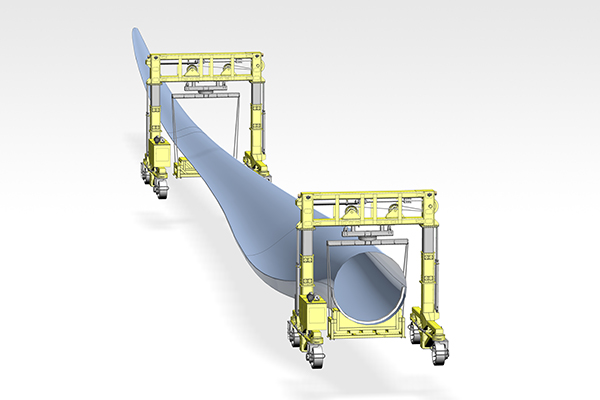

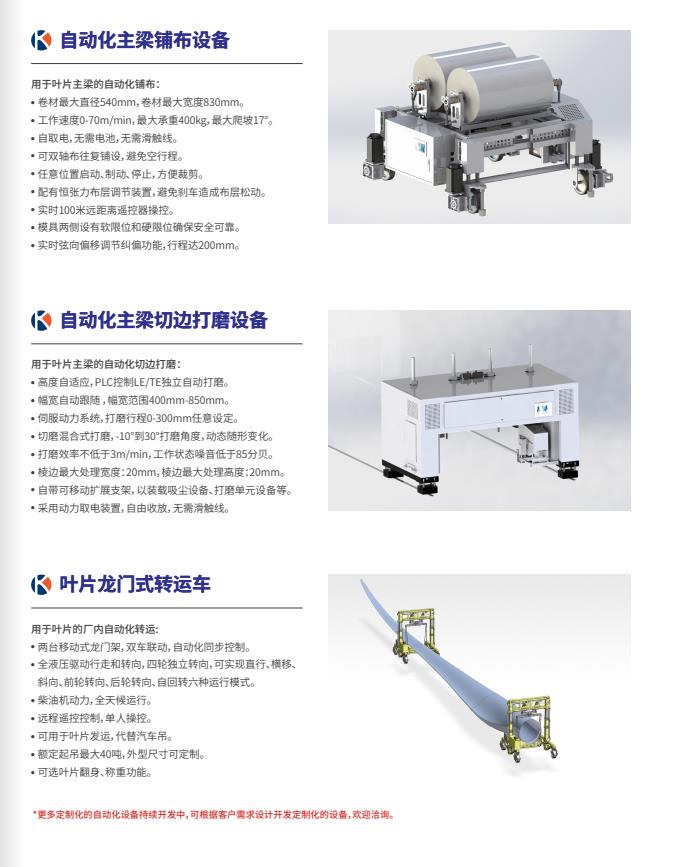

Gantry transfer vehicle

-

NDT equipment

-

Electrode material

-

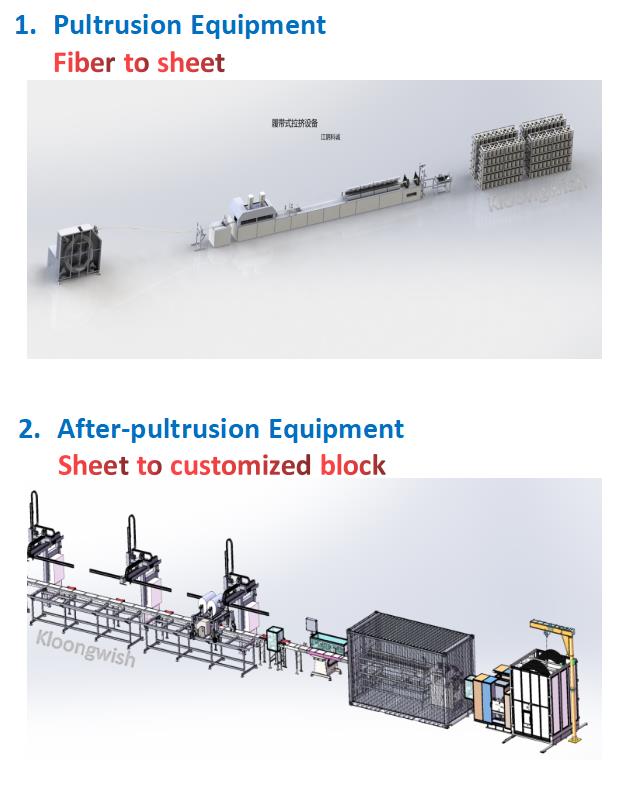

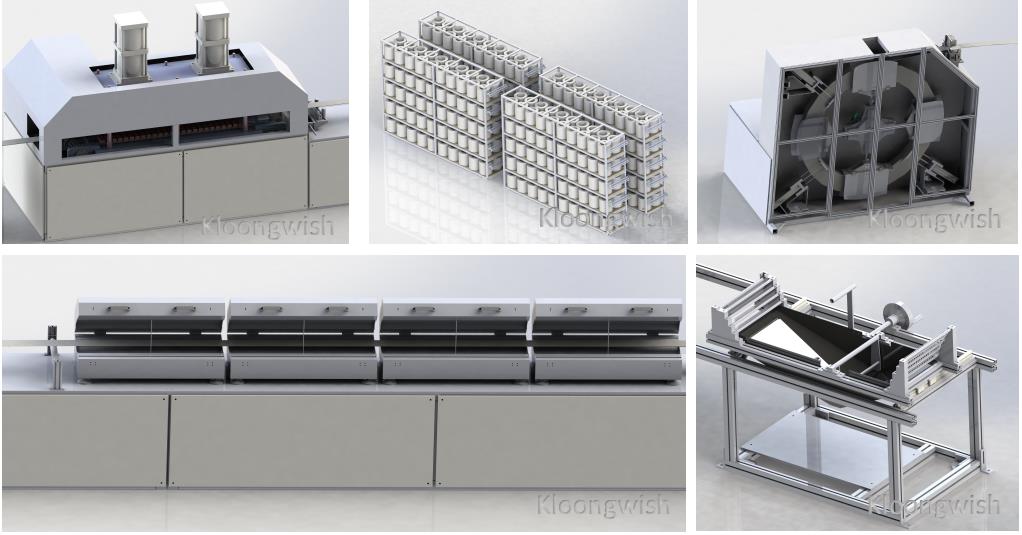

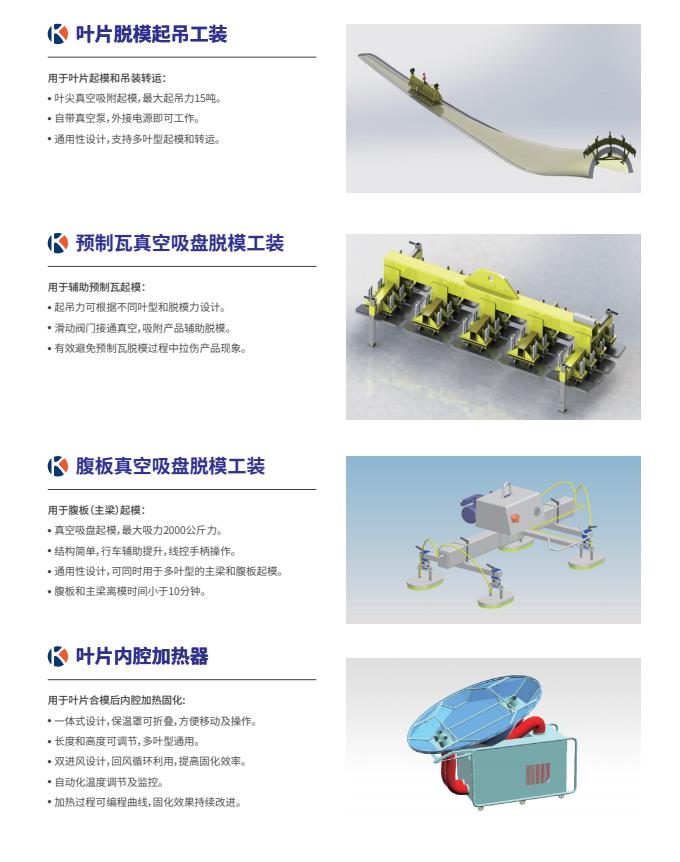

Automation equipment

-

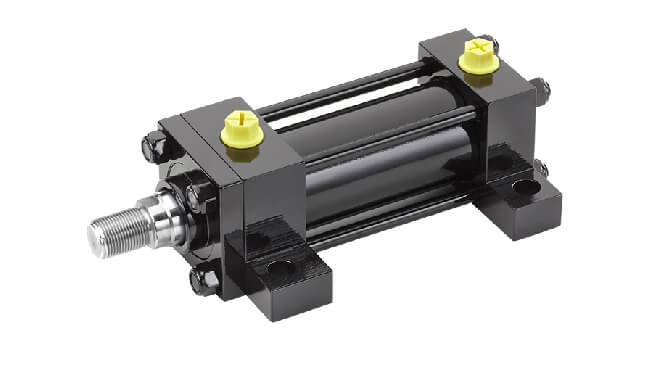

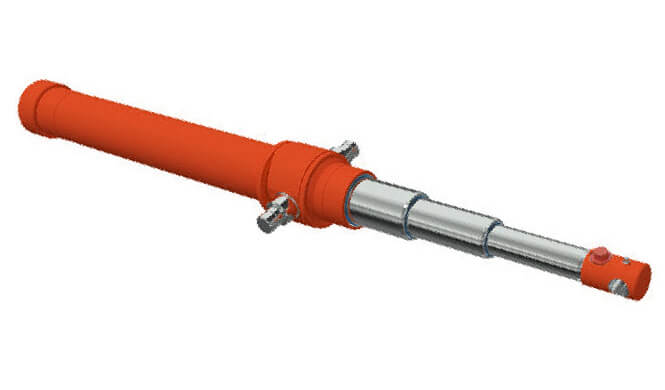

Hydraulic cylinders

-

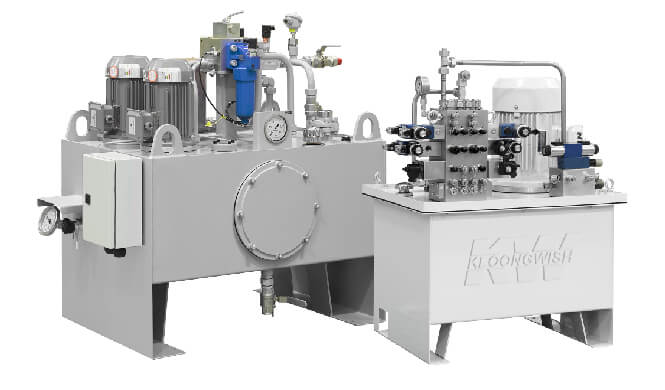

Hydraulic system

-

Mechanical structure

Applications

As we all know, every customer has specific ideas and needs. Using our accumulated market experience in the industry, we provide better and more suitable products, services and solutions for you, which can effectively increase the market value of machinery and equipment.

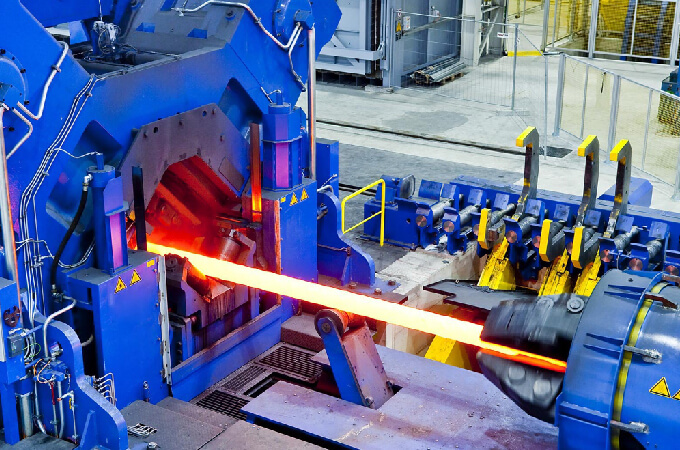

Main Industry

Metallurgy

Facing the constant test of metallurgical equipment in high temperature, dust and frequent action environment, the service life and durability of KLOONGWISH's hydraulic products can be trusted.

Automated industry

KLOONGWISH's hydraulic system fully meet the requirements of synchronization, high frequency and precise control of automatic equipment during synchronous operation. Choose us for reliable guarantee.

Mobile machinery

Our products provide machinery with continuous and reliable power and control for handling operations, creating higher mechanical efficiency for you and producing more value.

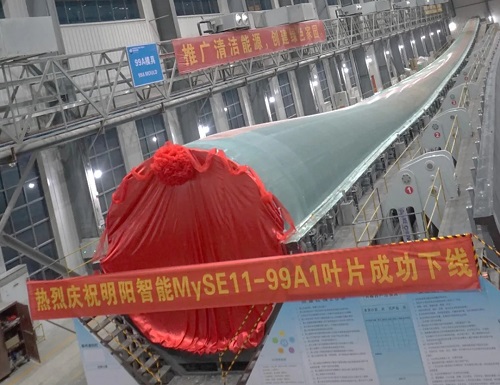

Wind power

Extremely rigorous tailor-made matching solutions, with reliable design and durable products, make their own contributions to the development of energy technology manufacturing.